Field service

VIMAB is located all over Sweden and is the leading valve service in the Nordic region. With our expertise and your own knowledge of your company's processes, we can improve and streamline valve maintenance with significant cost savings as a result. Feel free to engage us already at the planning stage, and we will propose the solutions that best suit your company.

What is valve service and how does it benefit my plant?

A valve service is carried out to ensure that you have full control over the proper functioning of your valves, so that you can detect any leaks and wear at an early stage and fix them before the problem occurs.

Checking, maintaining, repairing and possibly replacing your valves reduces costly production downtime and extends their lifetime and quality. It also reduces the environmental impact, as a timely repair can mean you don't have to replace your existing valves with new ones.

Our specially trained service technicians have all the necessary equipment and can quickly find the root cause of an abnormal wear or leak.

Our valve service - how it works

- We start by dismantling and cleaning the valve and its parts

- Gaskets and packing boxes are replaced

- Sealing surfaces are sanded

- We check the different parts of the valve for condition and wear; do any spare parts need to be replaced?

- We test the valve in a test bench with calibration and then perform a tightness check

- A sign with information on opening pressure and inspection date is mounted and sealed on the valves

- We provide you with a full-scale report and maintenance plan of the valves

Below you can read about the type of service and maintenance we offer for different types of valves:

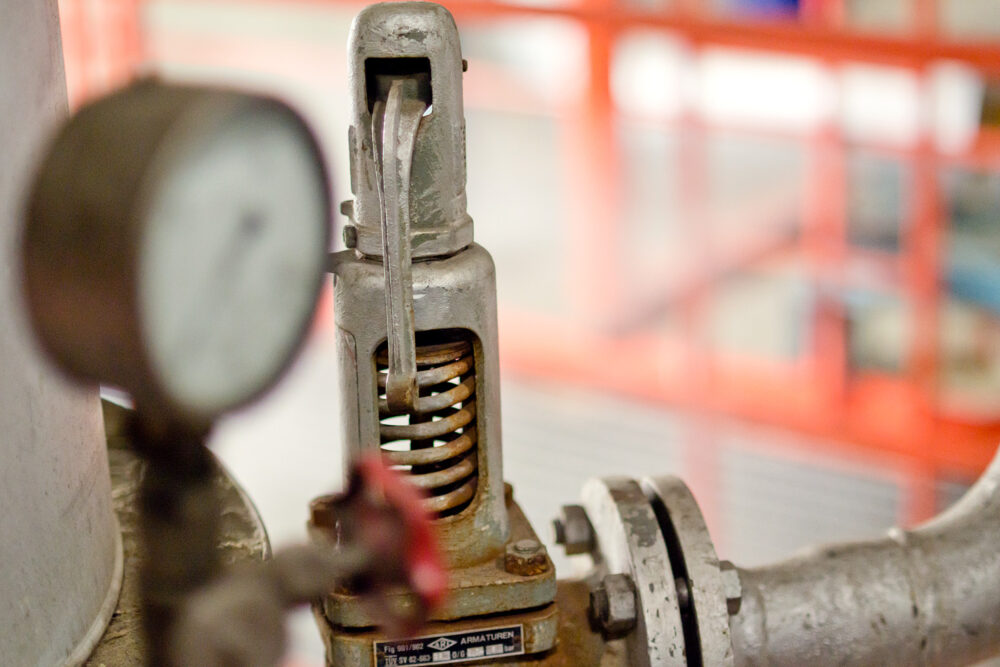

Safety valves

Leaky safety valves have negative environmental impacts and energy losses. They also protect staff and equipment and are therefore subject to legal requirements for regular checks.

We carry out

- Disassembly and assembly

- Renovation, functional and tightness check of the valve

- Functional check of safety valves in operation

Shut-off valves

Leaking shut-off valves can lead to high energy costs and process disruptions. In the worst case, it can also pose safety risks.

We carry out

- Disassembly and assembly

- Refurbishment and testing of actuators ? electric and pneumatic

- Renovation and tightness check of all parts of the valve

Control valves

Control valves are often complex and place high demands on qualified service. That's why we have trained technicians with expertise in the maintenance of control valves.

We carry out

- Disassembly and assembly

- Renovation of actuators - electric and pneumatic

- Adjustment of position switches.

- Renovation and tightness check of the valve

- Test of electric actuators in brake bench

Book service