The poppet valve ? the standard solution for small pipes

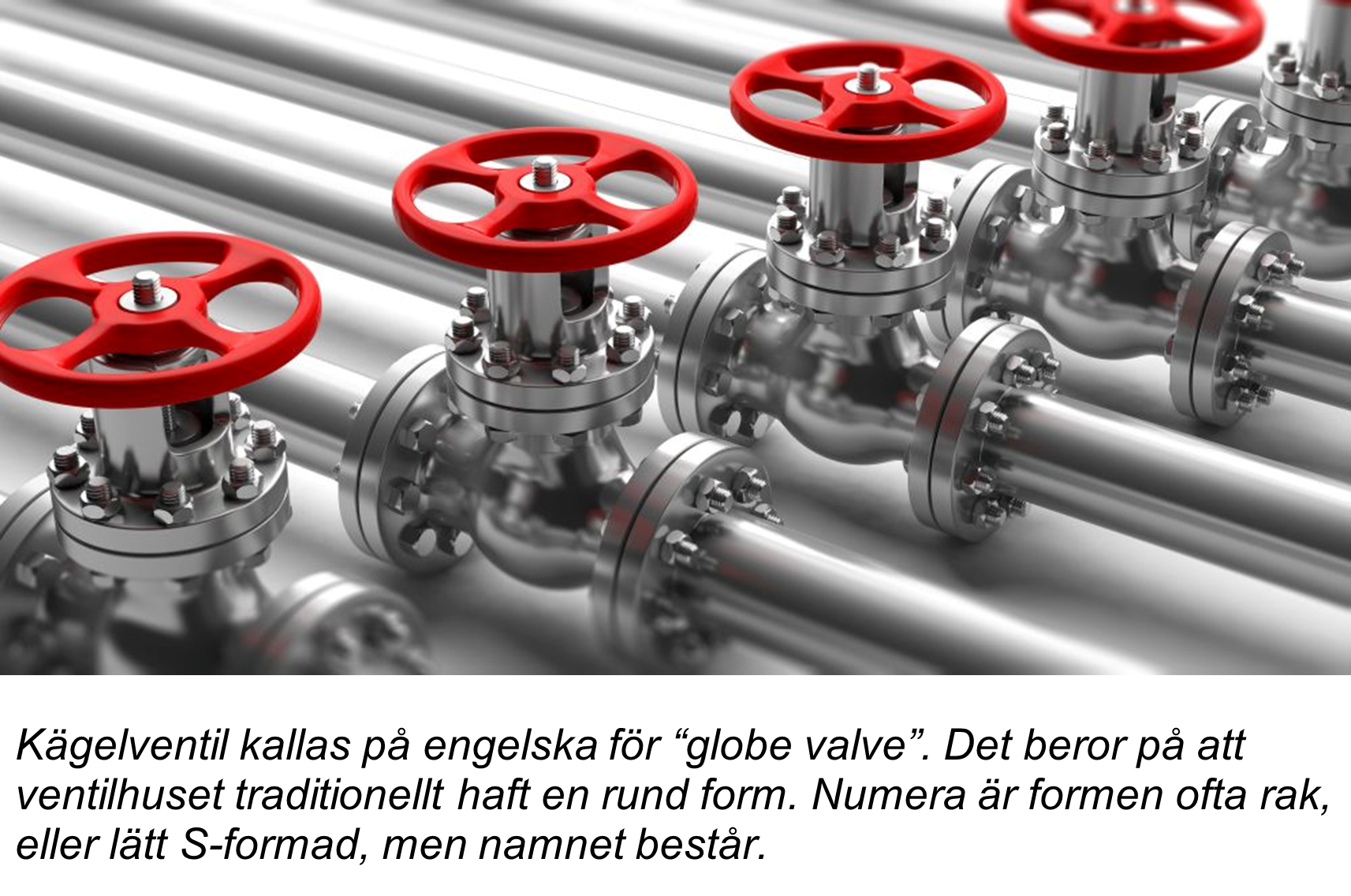

The globe valve is a simple type of valve often used on small pipes to regulate or stop the flow.

The globe valve is a common type of valve used to regulate or shut off a flow. The advantages of the valve type are that it is small and relatively cheap. It is most common on small diameter pipes, up to 65 mm. Globe valves are mainly used for easy flowing and volatile liquids and for gases such as vapour.

The poppet valve gets its name from the poppet, a raisable and lowerable sealing element that rests against the valve seat. It is lifted by turning the stem, which is threaded into the valve body. The main parts are the valve body, the seat, the plug, the stem and a stuffing box that prevents leakage around the stem. The valve may also have a bellows, which prevents aggressive media from coming into contact with the stuffing box.

Types of poppet valves

There are several different types of poppet valves. The main ones are shut-off valves and control valves. Control valves are used to influence the flow. Shut-off valves are used when you want to open or close completely, for example if you want to isolate a section of pipework so that you can work on it. They are also used to drain liquid or gas, or to release air from the system. A plug valve designed for flow control should not be used as a shut-off valve. Shut-off is a safety feature to make a section of pipework safe to work on. It is therefore necessary to be sure that the valve is completely closed, which a shut-off valve is designed to guarantee.

It is not possible to tell from the valve whether it is intended for shut-off or flow control, it depends on how it is designed on the inside. It is necessary to read the manufacturer's instructions before installation.

Direction of flow

Another thing that is stated in the manufacturer's instructions is the direction of flow. It is important that the plug valve is installed in the right direction. Sometimes valves are installed in the wrong direction, for example by people who are not familiar with the process. This can lead to abnormal wear on the valve. Some plug valves have different flow directions depending on the pressure in the pipe. This is also indicated in the manufacturer's instructions. Plug valves are also available as three-way valves, which allow the flow to be switched between two alternative flows.

Advantages and disadvantages

A disadvantage of the plug valve is that it reduces the flow by having the seat partially in the way of the flow. The flow also takes a slight S-shape through the valve body, which also contributes to reducing the flow. Advantages of the valve type are that it is easy to maintain, cost effective and space saving. It is easy to install and is available for flanged or welded installation. On pipes up to 65 mm, plug valves are almost always used. For shut-off and regulation of larger dimensions, other types of valves are used.

Treat the valve correctly

The plug valve needs to be exercised from time to time. The stem and stem nut should be lubricated with the right quality lubricant. Sometimes a spanner is used for valves that run slowly. This is a bad idea. The wrench provides leverage that causes the stem to turn with much more force than it is designed for. There is a reason why the steering wheel is the size it is. With a spanner, you can easily pull the valve apart and you may end up with bigger problems than you originally had.

Valve renovation

When a poppet valve arrives at Vimab, we first assess whether it is worth repairing. If the damage is extensive and the valve is not very expensive, it is easiest to install a new one. Once we have decided to proceed, the surface is blasted, sealing surfaces are sanded and new gaskets are fitted. The valve is tested in a test bench and the sealing is checked.

Sometimes valves come in with abnormal wear. This may be because the valve has been sitting too long without being exercised, or because it is the wrong type of valve for the application. In such cases, we contact the plant owner and try to get to the bottom of the problem. The process may have specific requirements for the valve material and design. The flow, pressure, temperature, viscosity and other parameters of the medium may require the valve to be designed in a certain way. Contact us at Vimab and we will help you choose the right plug valve.

See which poppet valves we have in stock right now ? click here.